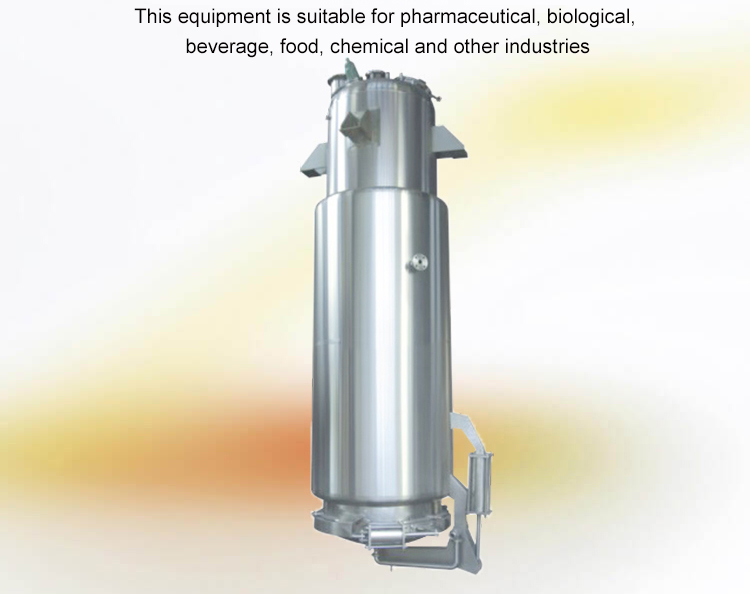

This equipment is suitable for normal pressure, pressurized water decoction, warm soaking, hot reflux, forced circulation, percolation, aromatic oil extraction and organic solvent recovery of plants and animals in the pharmaceutical, biological, beverage, food and chemical industries. In particular, dynamic extraction or countercurrent extraction has better effects, short time and high liquid content.

Equipment

The tank is equipped with CIP cleaning automatic rotating spray ball, thermometer, pressure gauge, explosion-proof sight hole lamp, sight glass, quick-opening feeding port, etc. to ensure easy operation and meet GMP standards. The inner cylinder of the equipment is made of imported SUS304 and SUS316L, and aluminum silicate is used for insulation.

Automated extraction workshop

1. Real-time monitoring and management of process status

2. Process setting makes the control process more perfect

3. Simple and easy-to-understand operation interface, easy to operate

4. Process parameters are detected online, displayed in real time and recorded and archived

5. Real-time online analysis, online problem solving and historical query

6. Strengthen production data management to ensure product quality

Optional slag door opening method

The cover can be opened and closed automatically, and three cylinders are used for control. At the same time, a safety device is added to prevent accidental operation, with a high safety factor. Suitable for small and medium-sized slag outlets.

Fully automatic opening and closing of the tank cover; high temperature and high pressure extraction can be achieved, and the rotary ring type can reach more than 3Bar, which provides more options for the extraction process, and can also adapt to some special process requirements. It is safe and reliable, has sufficient safety protection functions, and the extraction tank is leak-free.